Qualification summary

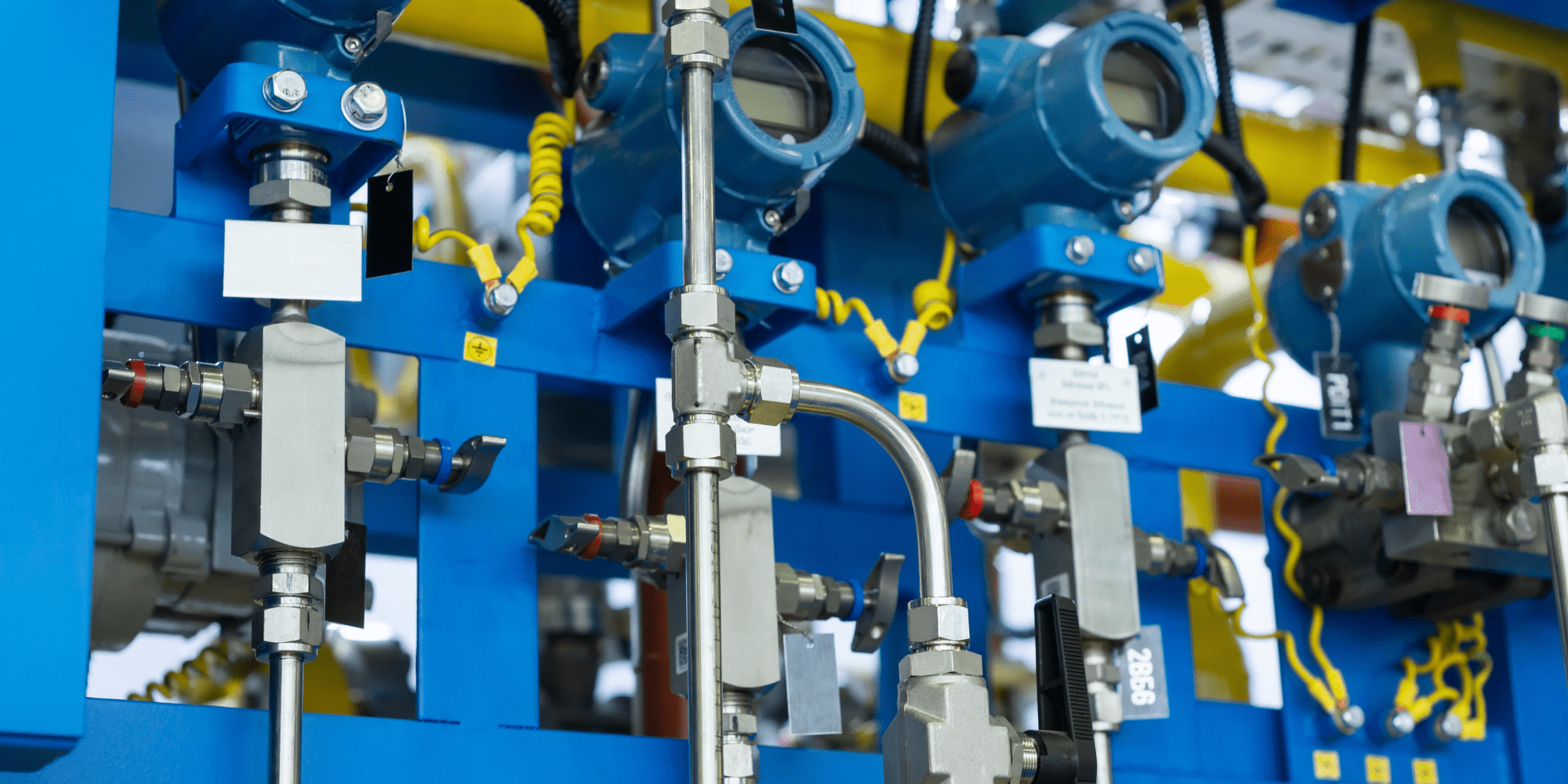

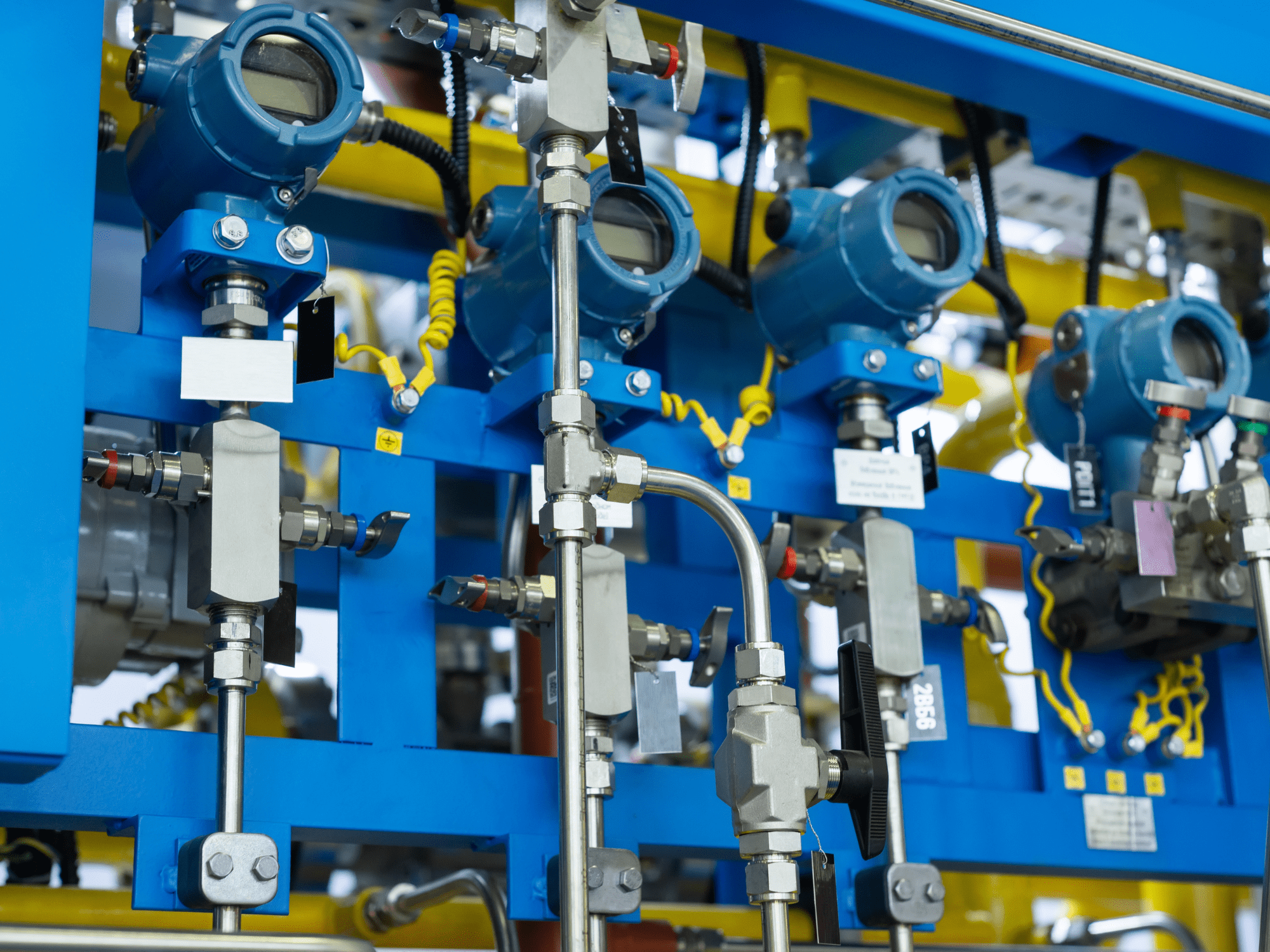

Based on National Occupational Standards (NOS), this Level 3 Diploma in Engineering Construction Maintenance (RQF) – Instrumentation and Control Pathway includes units on removing and replacing components including checking for defects, positioning and installing plant and equipment and more.

The objective of this vocational qualification is to provide recognition that a learner has demonstrated the required level of technical competence to be qualified to work as a maintenance technician on engineering construction plant and systems in 1 of the following disciplines (pathways):

- Electrical

- Instrumentation and control

- Mechanical

The learner is required to select ONE discipline pathway ONLY when registering on the qualification. Successful completion of the qualification pathway will lead to the learner being awarded one of the following:

- ECITB Level 3 Diploma in Engineering Construction Maintenance (RQF) – Electrical

- ECITB Level 3 Diploma in Engineering Construction Maintenance (RQF) – Instrumentation and Control

- ECITB Level 3 Diploma in Engineering Construction Maintenance (RQF) – Mechanical

Where is this qualification delivered?

To complete this qualification learners must enrol with one of ECITB’s Approved Centres listed below.

Aberdeen Skills and Enterprise Training Limited

Test:

Electrical Installation, Electrical Maintenance, Instrument and Controls, mechanical fitting, Mechanical Joint Integrity, mechanical maintenance, Pipefitting, Plating, Production Operator, Small Bore Tubing

Course:

Mechanical Joint Integrity

Qualification:

Electrical Maintenance, instrument and controls, Mechanical Maintenance

Aberdeen City Campus, Gallowgate, Aberdeen, AB12 3LE Get directionsto Aberdeen Skills and Enterprise Training Limited

01224 859662

View organisationAberdeen Skills and Enterprise Training Limited

GenII Engineering & Technology Training Ltd

Course:

electrical installation, pipefitting

Qualification:

Design and Draughting, Electrical Fitting, Electrical Maintenance, instrument and controls, Mechanical Fitting, Mechanical Maintenance, Pipefitting, Plating, Project Controls

CCNSG:

CCNSG, CCNSG Test-Only

Lillyhall Industrial Estate, Blackwood Rd, Lillyhall, Workington, FK2 9AD Get directionsto GenII Engineering & Technology Training Ltd

01900 701300

Margaret.Edmondson@gen2training.co.uk

View organisationGenII Engineering & Technology Training Ltd

East Coast College

Qualification:

Electrical Fitting, Electrical Maintenance, Instrument & Controls, Mechanical Fitting, Mechanical Maintenance, Pipefitting, Plating, Project Controls

CCNSG:

CCNSG

St. Peter's Street, Lowestoft, NR32 2NB Get directionsto East Coast College

https://www.eastcoasttrainingacademy.co.uk/course/ccnsg/

01502 525041

trainingacademy@eastcoast.ac.uk

View organisationEast Coast CollegeThe International Assessment Centre

Qualification:

Design and Draughting, Electrical Fitting, Electrical Maintenance, Instrument & Controls, Mechanical Fitting, Mechanical Maintenance, Moving Loads/Rigging, Pipefitting, Plating, Steel Erecting, Welding

3A Bowes Road Business Park, Middlesbrough, TS2 1LU Get directionsto The International Assessment Centre

http://www.intlassessmentcentre.com

07941 330141

View organisationThe International Assessment CentreWhat is the qualification structure?

To achieve this qualification learners must complete the 9 mandatory units shown below. A learner must successfully meet the selected discipline pathway requirements of all 9 units to attain this qualification.

It takes the average candidate 1,886 hours to complete this qualification. This includes 952 hours of time with a teacher, trainer or assessor, the remaining hours are unsupervised time for learning and producing evidence to be assessed.

The amount of time taken to achieve this qualification is typically 36 months.

Qualification units

Unit MPS01

Work safely, effectively, ethically and sustainably, managing risk and hazards (plus employer desirable behaviours)

Unit MPS02

Interpret and follow maintenance documentation and procedures including prepare and reinstate the work area

Unit MPS03

Disassembly of plant and equipment

Unit MPS04

Removal and replacement of components including checking for defects

Unit MPS05

Repair of components

Unit MPS06

Assemble components

Unit MPS07

Position and install plant and equipment

Unit MPS08

Preventative and corrective maintenance

Unit MPS09

Fault diagnosis and feasibility of repairing faults

Find out more

Are you looking to take this qualification?

Find an approved centreWant to become an ECITB approved centre?

Find out moreAlternatively, contact our team on...

qualifications@ectib.org.uk