Qualification summary

The qualification’s final registration date has now closed, we are unable to accept new registrations. Learners who were registered on or before 30 June 2024 will be able to continue to take assessments to complete their qualification. The certification end date is 30 June 2027.

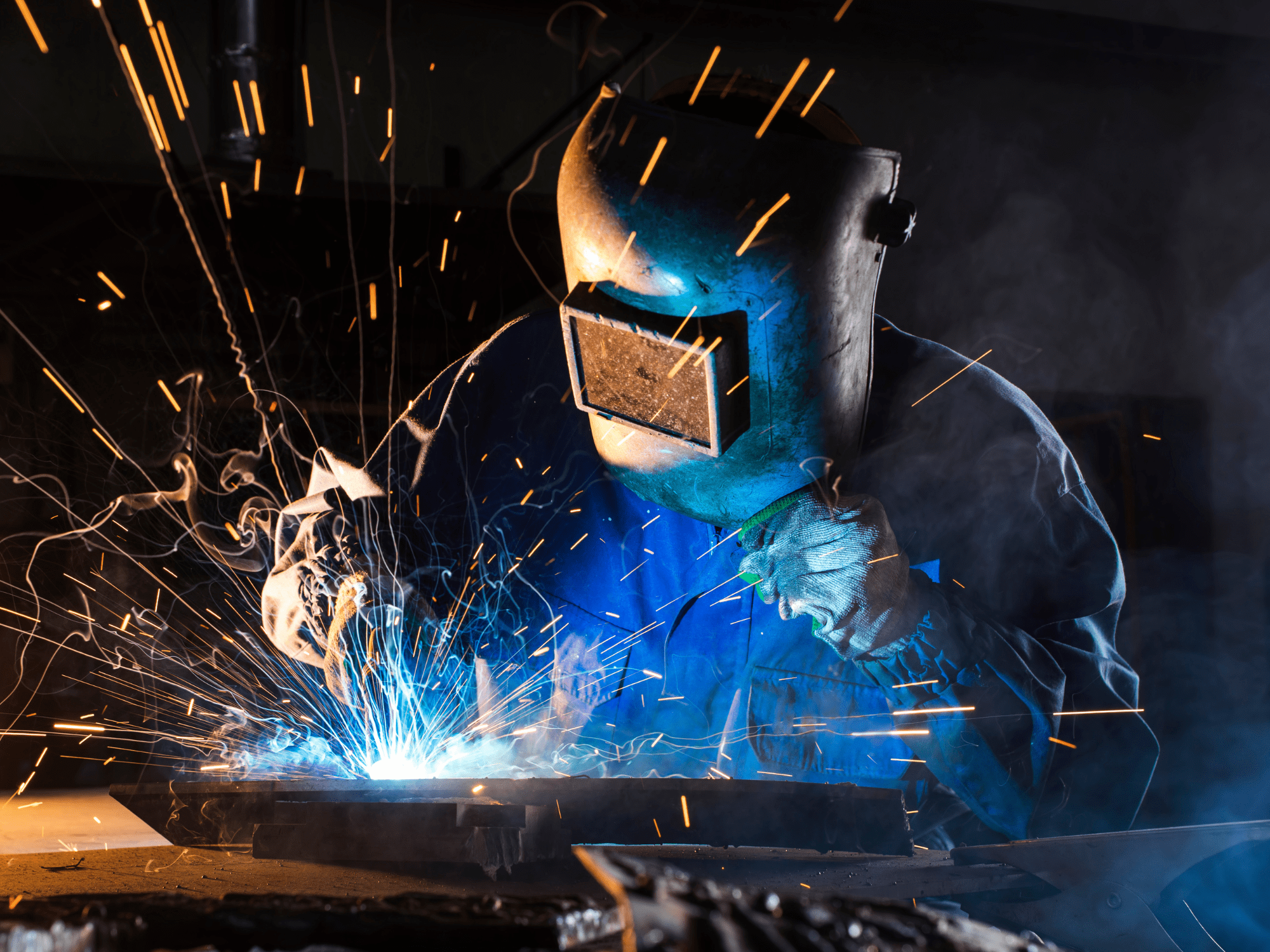

Based on National Occupational Standards (NOS), this Diploma in Welding Engineering Construction Plate at SCQF Level 7 supports learners to interpret welding procedures, specifications and standards in engineering construction, contribute to effective working relationships and more.

ECITB requires that evidence of competence must be drawn from and reflect activity undertaken by the learner in the workplace. The workplace is defined as the learner’s normal place of work for their occupation.

In the units of assessment some learning outcomes and associated assessment criteria relate to the knowledge that enables a learner to perform competently. Evidence must be collected that verifies this knowledge is present.

Where is this qualification delivered?

To complete this qualification learners must enrol with one of ECITB’s Approved Centres listed below.

Hartlepool Training Ltd

Test:

Confined Space

Course:

abrasive wheels, confined space, Firewatcher

Qualification:

Electrical Fitting, Erecting, Mechanical Fitting, Mechanical Maintenance, Moving Loads, Pipefitting, Plating, Rigging, Welding

CCNSG:

CCNSG

Ainsley St, Hartlepool, TS25 1TZ Get directionsto Hartlepool Training Ltd

http://www.hartlepooltraining.co.uk

01429 868657

brian.goodlad@hartlepooltraining.co.uk

View organisationHartlepool Training Ltd

3t Training Services Limited

Test:

Electrical Installation, Electrical Maintenance, Industrial Coatings, Mechanical Joint Integrity, Pipefitting, Plating, Production Operator, Small Bore Tubing, Thermal Insulation

Course:

Appointed Persons Moving Loads, CCNSG National, CCNSG Renewal, confined space, Mechanical Joint Integrity, pipefitting, plating, rigging, Small Bore Tubing, Supervisor & Chargehand training, working at height

Qualification:

Pipefitting, Plating, Rigging, Welding

CCNSG:

CCNSG

Units 3 & 4 Jupiter Court, Orion Business Park,Tyne Tunnel Trading Estate, North Shields, NE29 7SE Get directionsto 3t Training Services Limited

0844 800 1810

View organisation3t Training Services LimitedThe International Assessment Centre

Qualification:

Design and Draughting, Electrical Fitting, Electrical Maintenance, Instrument & Controls, Mechanical Fitting, Mechanical Maintenance, Moving Loads/Rigging, Pipefitting, Plating, Steel Erecting, Welding

3A Bowes Road Business Park, Middlesbrough, TS2 1LU Get directionsto The International Assessment Centre

http://www.intlassessmentcentre.com

07941 330141

View organisationThe International Assessment CentreForth Valley College of Further and Higher Education

Test:

Mechanical Joint Integrity, Pipefitting

Course:

Drone training

Qualification:

Design and Draughting, Electrical Maintenance, Instrument & Controls, Mechanical Fitting, Mechanical Maintenance, Pipefitting, Plating, Welding

Grangemouth Road,Falkirk, FK2 9AD Get directionsto Forth Valley College of Further and Higher Education

https://www.forthvalley.ac.uk/

01324 403173

centre.coordinator@forthvalley.ac.uk

View organisationForth Valley College of Further and Higher EducationWhat is the qualification structure?

To achieve this qualification learners must complete all 4 mandatory units plus a minimum of 2 optional units. Two different welding processes from the following list must be completed:

- TIG welding

- TIG/MMA welding

- MMA welding

- MIG/MAG welding

- Flux-cored arc welding

Gouging is not a welding process but is provided as an extra optional unit.

Qualification units

CO-S1 (mandatory unit)

Contribute to effective working relationships in engineering construction

CO-S2 (mandatory unit)

Work safely and minimise risk in engineering construction

CO-S3 (mandatory unit)

Identify and deal with hazards and emergencies in the engineering construction work environment

Welding Plate – S7 (mandatory unit)

Interpret welding procedures, specifications and standards in engineering construction

Welding Plate – S1 (optional unit)

Join plate in engineering construction by TIG welding

Welding Plate – S2 (optional unit)

Join plate in engineering construction by flux cored welding

Welding Plate – S3 (optional unit)

Join plate in engineering construction by TIG/MMA welding

Welding Plate – S4 (optional unit)

Join plate in engineering construction by MMA welding

Welding Plate – S5 (optional unit)

Join plate in engineering construction by MIG/MAG welding

Welding Plate – S6 (extra optional unit)

Gouging in engineering construction for welding activities

Find out more

Are you looking to take this qualification?

Find an approved centreWant to become an ECITB approved centre?

Find out moreAlternatively, contact our team on...

qualifications@ectib.org.uk