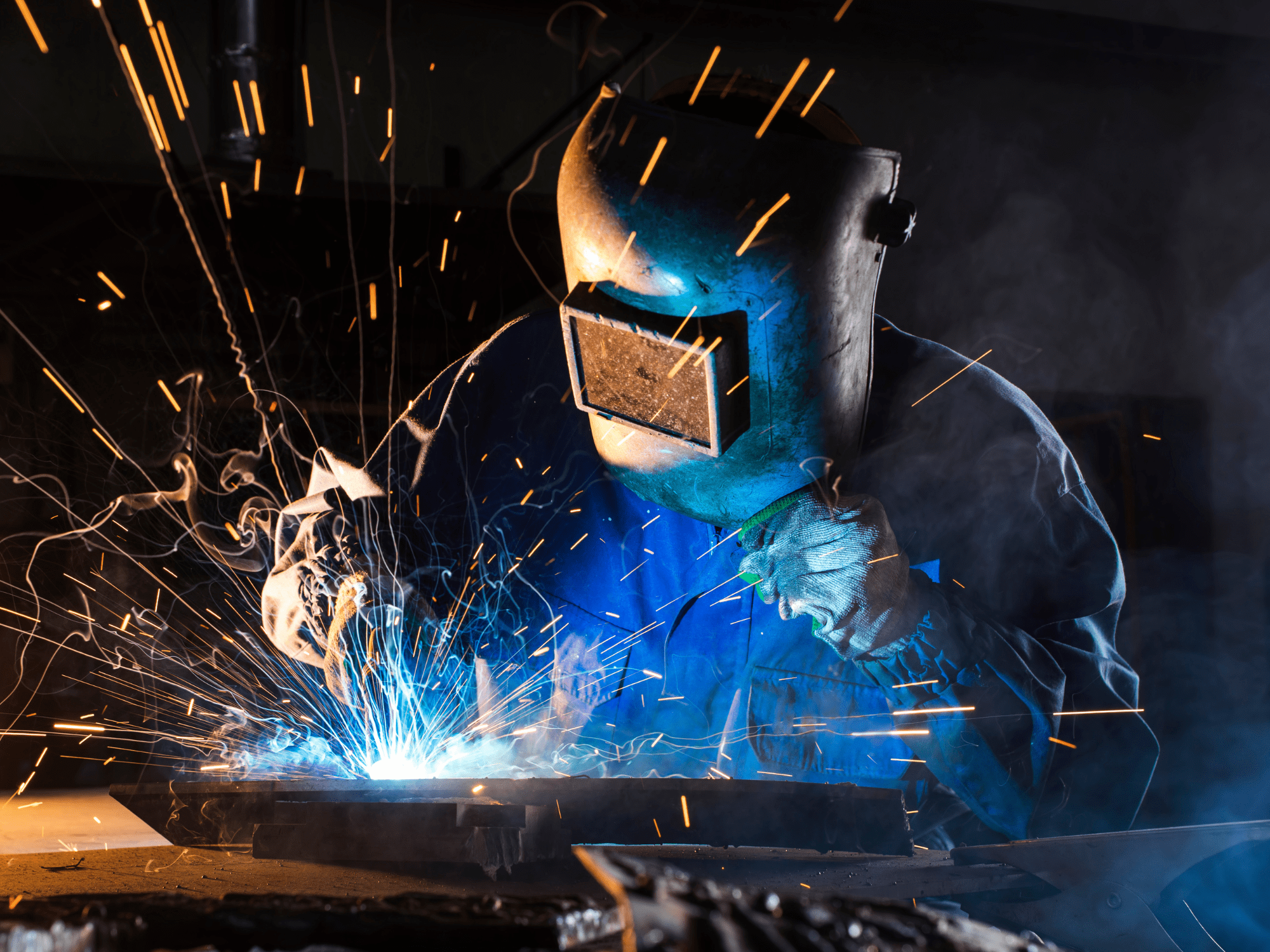

Accurately weld pipe and plate joints using a range of welding techniques

ECITB approved provider training for upskilling welders

Gain independent verification of technical skills with ECITB's technical tests

ECITB scholarships are available for those interested in becoming welders

Approved courses from providers

Reskill welding

Technical tests

Join materials by manually controlled welding process

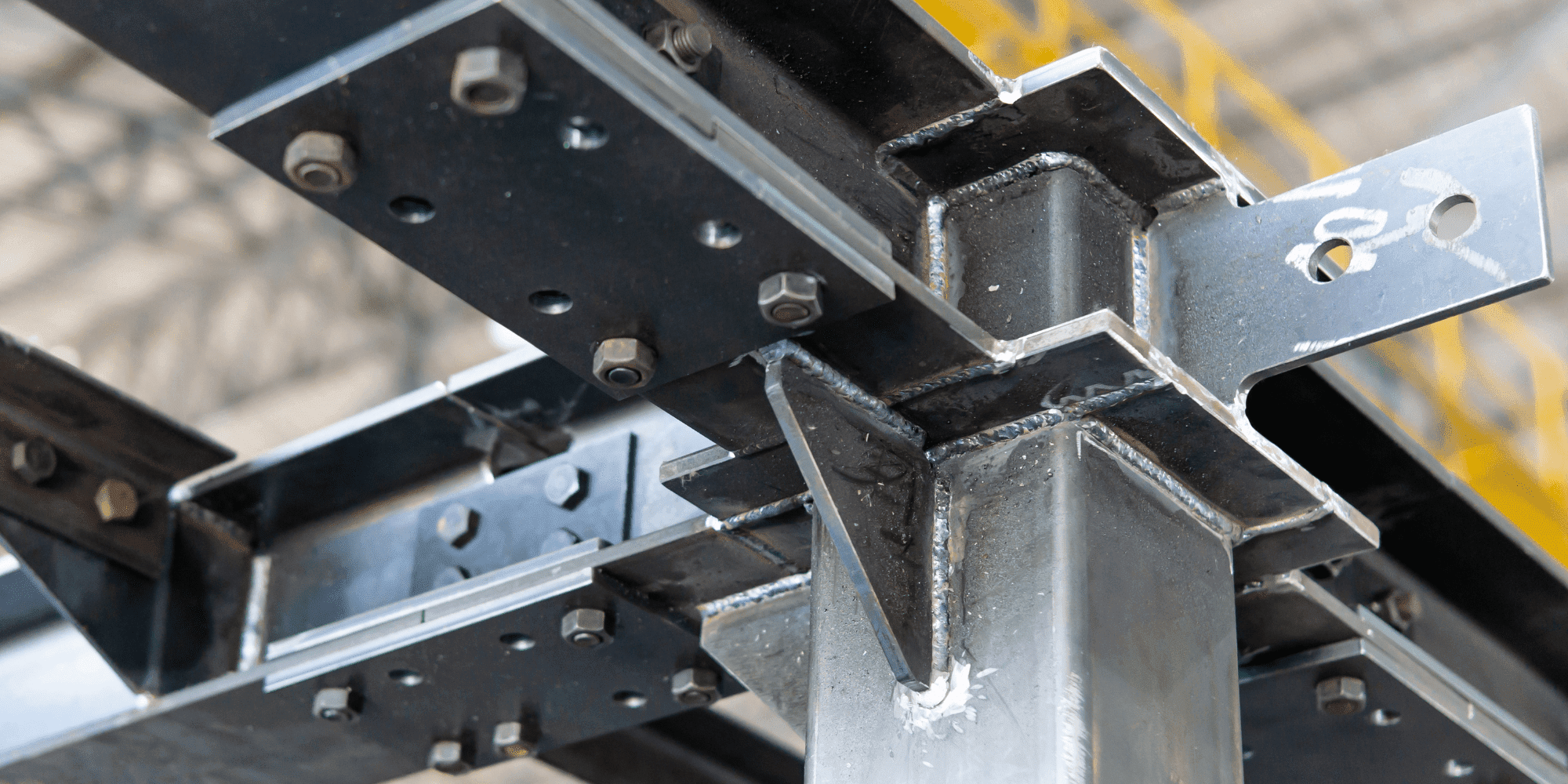

These tests confirm the technical competence of a welder on nuclear new build to safely prepare, set-up and carry out welding to the required, specific standards on a nuclear site.

Non-critical welding pipe and plate

- non-critical welding pipe tests: butt welds using MIG, MMA and TIG welding

- non-critical welding plate tests: 1G and 2G butt welds and 1F and 2F single-sided fillet welds using MIG, MMA and TIG plate welding and in FCAW thick plate welding (3G single V butt weld)

Welding for nuclear new builds

This range of practical tests assess a welder on nuclear new build’s ability to prepare, set-up and carry out welding to the required, specific standards on a nuclear site.

Welding preparation pipe and plate

This series of tests confirm the candidate can safely and correctly prepare and set up a variety of butt joints in different pipe and plate materials (carbon and low alloy, stainless steel, nickel and nickel alloy, aluminium) ready for the selected welding process to the welder approved standards (in BS EN 287):

- Welding pipe preparation: 12 individual tests for a variety of different pipe materials and incline positions in preparation to use different welding techniques.

- Welding plate preparation: 14 individual tests for a variety of different plate materials in preparation to use different welding techniques

Qualifications

Related disciplines

Sign up for updates

Your information will be used to subscribe you to our e-newsletter.

For more information, please see our Privacy Notice.