Tests and qualifications developed with industry experts

Gain independent verification of technical skills with ECITB's technical tests

Gain independent verification of occupational competence with ECITB's regulated qualifications

ECITB mechanical scholarships available

Approved courses from providers

Onsite pipe cutting and pipe end weld preparation

Training on the theory and practical skills required for the trainee to be able to safely and effectively cut and prepare pipework for welding to specification.

Onsite joint face machining - basic

Onsite joint face machining - advanced

Training in the health, safety, quality, technical and practical skills required to carry out advanced joint facing of RTJ flanges and clamp hubs using portable machine tools.

Onsite milling

Training in health, safety, quality, technical and practical aspects of milling of pump beds and shaft keyways using portable machine tools.

Technical tests

Machining

This series of technical tests verifies the mechanical fitter’s ability to safely and accurately prepare and use the following:

- lathes for turning operations and advanced turning operations

- milling machines for milling and advanced milling operations

- horizontal boring

- surface and cylindrical grinders

- radial arms drills

Mechanical fitting

This range of technical tests verifies the mechanical fitter’s ability to safely and effectively:

- accurately measure

- mark out

- make and fit

- assemble components

- prepare for installation

- position plant and equipment

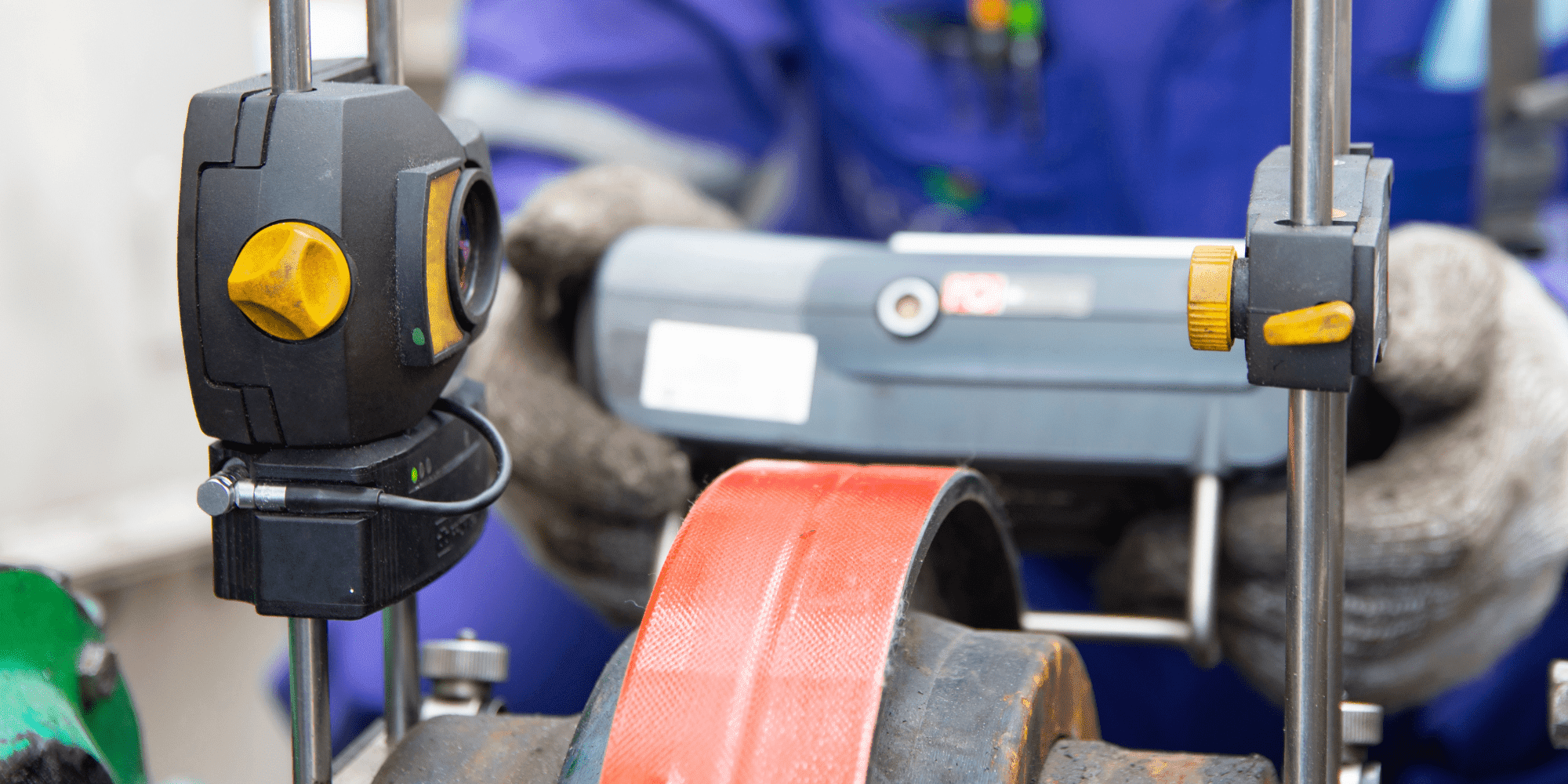

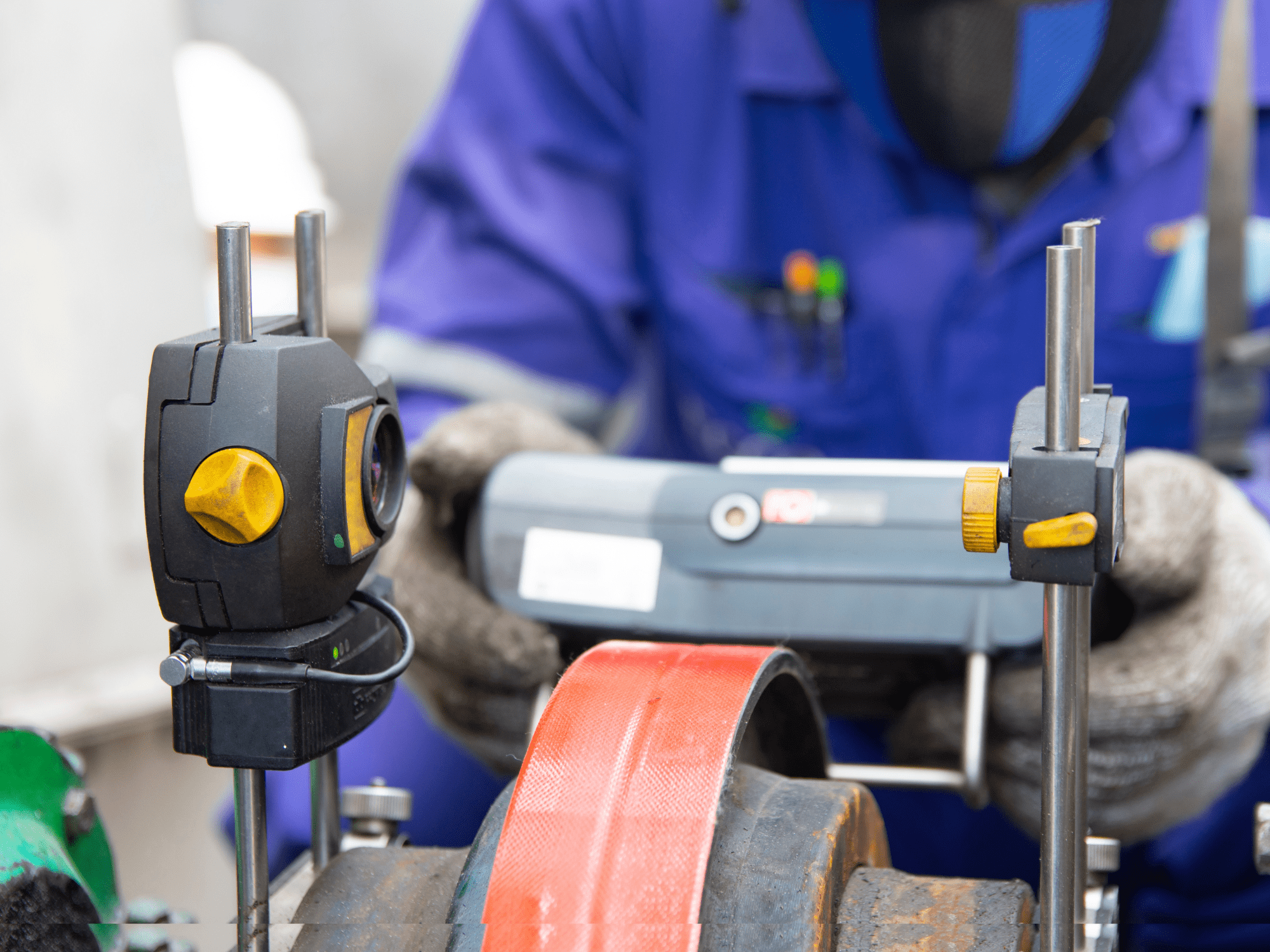

- align, level and set equipment

- install drive systems

- repair faults

- diagnose faults

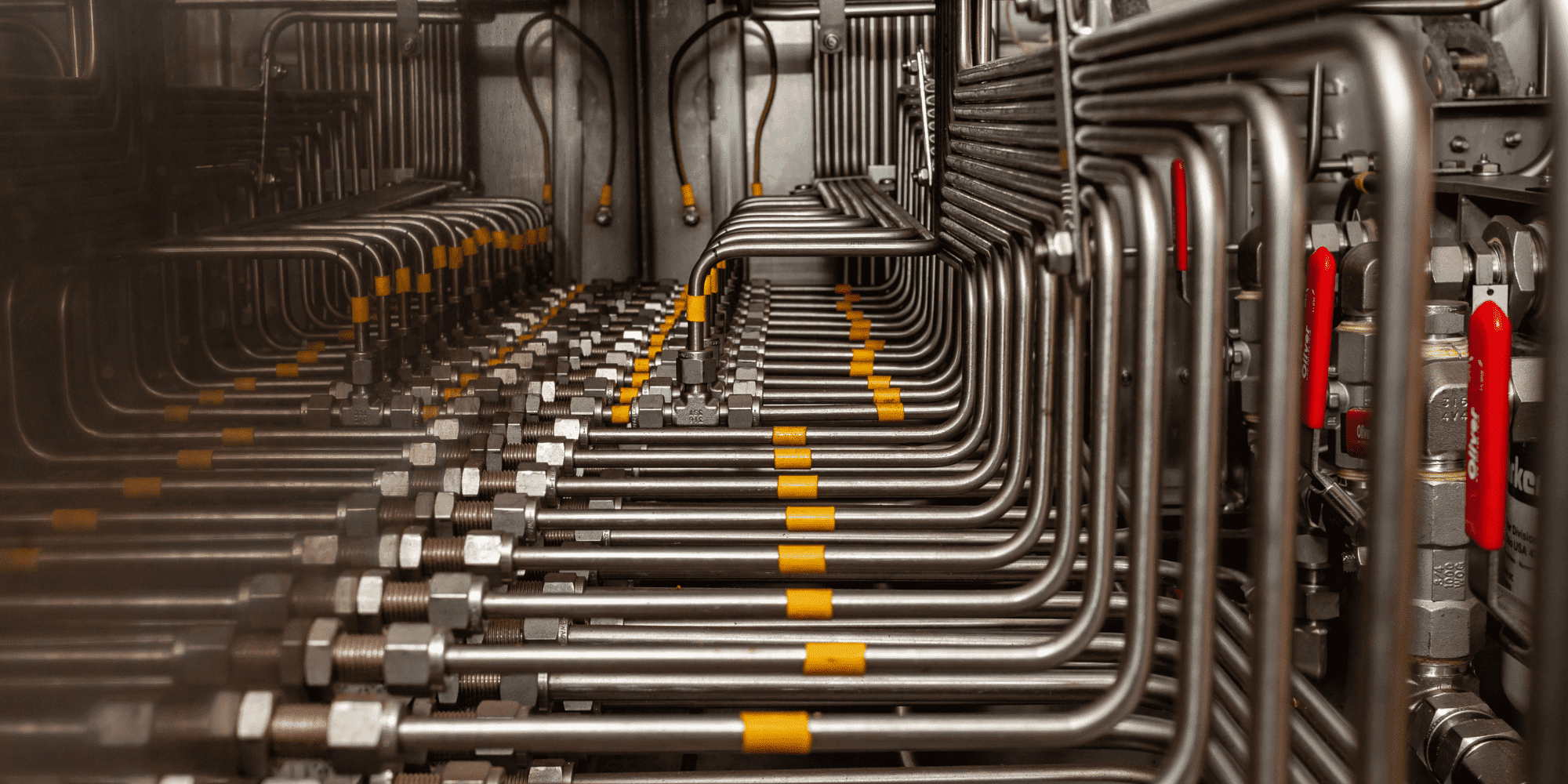

- prepare and assemble small bore pipework

- remove and install mechanical components

Mechanical maintenance

A range of technical tests which verify the maintenance technician’s knowledge and ability to safely and effectively maintain a range of different equipment and systems, including:

- hydraulic, pneumatic, compressed air, brake, heating, ventilating and air conditioning systems

- shafts, bearings and seals

- pumps

- geared and actuating mechanisms

- belt and chain drives

- shafts and couplings

- clutches

- valves

- diesel engines

Onsite machining

A series of technical tests that verify the candidate’s technical competence to undertake:

Qualifications

Related disciplines

Connected Competence

Mechanical tests are available under Connected Competence. Through industry-recognised, standardised testing, Connected Competence assures an ongoing base level of technical competence for workers across the engineering construction industry (ECI) to create a safer, more competent and transferable workforce.

Find out more about Connected CompetenceSign up for updates

Your information will be used to subscribe you to our e-newsletter.

For more information, please see our Privacy Notice.